My Garage

My Account

Cart

Genuine Ford Fusion ABS Sensor

ABS Wheel Speed Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

32 ABS Sensors found

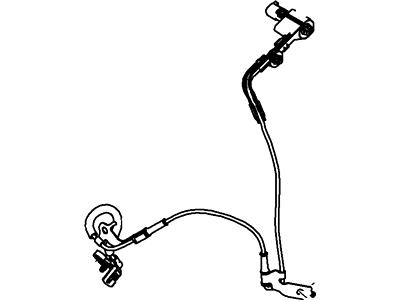

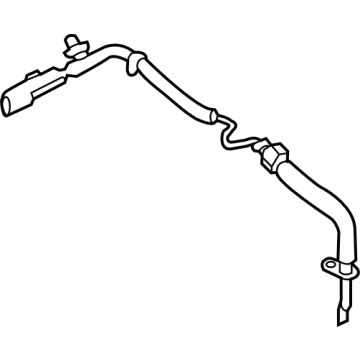

Ford Fusion Sensor Assembly

Part Number: JG9Z-2C205-A$43.55 MSRP: $69.45You Save: $25.90 (38%)Ships in 1-2 Business Days

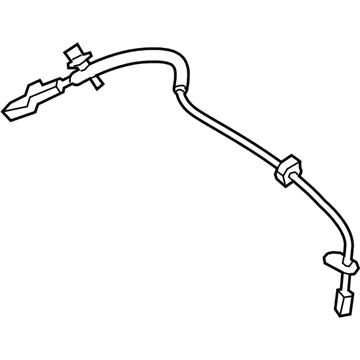

Ford Fusion Sensor Assembly

Part Number: JG9Z-2C204-A$38.87 MSRP: $62.00You Save: $23.13 (38%)Ships in 1-2 Business DaysFord Fusion Sensor Assembly

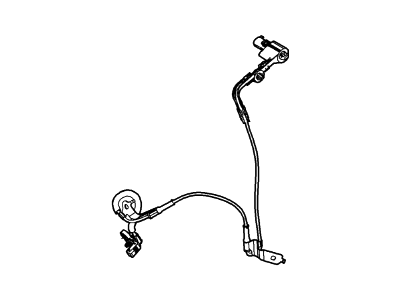

Part Number: DG9Z-2C205-B$43.55 MSRP: $69.45You Save: $25.90 (38%)Ships in 1-2 Business DaysFord Fusion Sensor Assembly

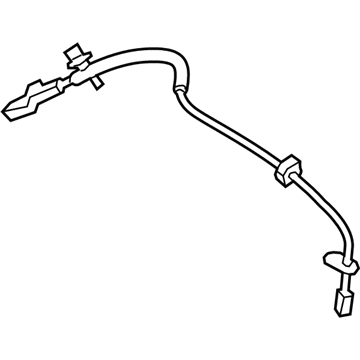

Part Number: DG9Z-2C204-B$38.87 MSRP: $62.00You Save: $23.13 (38%)Ships in 1-2 Business DaysFord Fusion Sensor Assembly

Part Number: DG9Z-2C190-G$35.68 MSRP: $56.91You Save: $21.23 (38%)Ships in 1-3 Business DaysFord Fusion Sensor Assembly

Part Number: DG9Z-2C190-C$35.68 MSRP: $56.91You Save: $21.23 (38%)Ships in 1-3 Business DaysFord Fusion Speed Sensor Assembly

Part Number: AE5Z-2C182-C$27.36 MSRP: $40.00You Save: $12.64 (32%)Ships in 1-3 Business DaysFord Fusion Speed Sensor Assembly

Part Number: AE5Z-2C182-A$27.61 MSRP: $39.33You Save: $11.72 (30%)Ships in 1-3 Business DaysFord Fusion Speed Sensor Assembly

Part Number: 6E5Z-2C187-AA$27.36 MSRP: $40.00You Save: $12.64 (32%)Ships in 1-3 Business DaysFord Fusion Sensor Assembly

Part Number: DG9Z-2C190-J$47.52 MSRP: $80.00You Save: $32.48 (41%)Ships in 1-2 Business DaysFord Fusion Sensor Assembly

Part Number: AE5Z-2C205-B$60.26 MSRP: $101.64You Save: $41.38 (41%)Ships in 1-2 Business Days

Ford Fusion Sensor Assembly

Part Number: K2GZ-2C190-H$95.15 MSRP: $157.27You Save: $62.12 (40%)Ships in 1-3 Business DaysFord Fusion Sensor Assembly

Part Number: 6E5Z-2C205-AA$60.26 MSRP: $101.64You Save: $41.38 (41%)Ships in 1-3 Business DaysFord Fusion Sensor Assembly

Part Number: K2GZ-2C190-E$87.55 MSRP: $141.82You Save: $54.27 (39%)Ships in 1-3 Business DaysFord Fusion Sensor Assembly

Part Number: DG9Z-2C190-L$35.68 MSRP: $56.91You Save: $21.23 (38%)Ships in 1-3 Business DaysFord Fusion Speed Sensor Assembly

Part Number: 6E5Z-2C182-AA$27.61 MSRP: $39.33You Save: $11.72 (30%)Ships in 1-3 Business DaysFord Fusion Sensor Assembly

Part Number: K2GZ-2C190-G$90.24 MSRP: $146.18You Save: $55.94 (39%)Ships in 1-3 Business DaysFord Fusion Sensor Assembly

Part Number: K2GZ-2C190-F$93.94 MSRP: $152.18You Save: $58.24 (39%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 32 Results

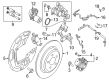

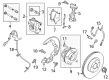

Ford Fusion ABS Sensor

We provide a wide range of Ford Fusion ABS Sensor at the best prices possible. If you need Ford Fusion ABS Sensor, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

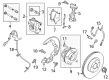

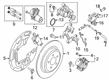

Ford Fusion ABS Sensor Parts Questions & Experts Answers

- Q: What is the general information about the anti-lock brake system and ABS Sensor on Ford Fusion?A:The anti-lock brake system is used to keep the vehicle steerable, on the right path and achieve the best possible braking in extreme conditions on most of the types of road by; measuring the speed of the rotation of each wheel and regulate the brake fluid pressure to avoid wheel locking. It consists of three main components: tire speed sensors, an electronic control unit or a central processing unit and a hydraulic unit. Each of the four wheel-speed sensors sends a variable voltage signal to the control unit, which compares these signals in order to observe whether or not a wheel is just about to lock up; the hydraulic unit will in turn change the brake pressure by means of electrically operated solenoid valves. If something is wrong, there will be an ABS warning light on the dashboard, but one should check the wiring harness of the ABS more closely, for example near each wheel, because there can be signs of wear or rubbing. Every time the warning light stays on during operation, there is a need to have the ABS system checked more closely, basic diagnostic includes checking the brake fluid level, tightening electrical connections, replacing fuses, and checking the wiring harness. In case these checks do not solve the problem, the unit demands professional diagnosis and repair by a professional technician. For wheel speed sensor removal procedure, loosening of lug nuts, raising of the vehicle, switching off the ignition, tracing the sensors wiring, detaching of the wiring, the removal of the mounting bolt and eventually the extraction of the sensor. Installation reversed the process as all parts must be tightened as much as possible.