My Garage

My Account

Cart

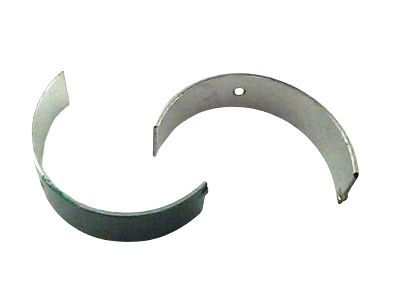

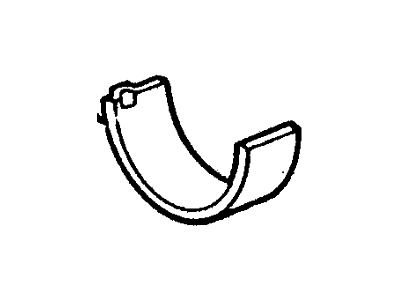

Genuine Ford Explorer Sport Trac Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Rod Bearings found

Ford Explorer Sport Trac Connecting Rod Bearing

Part Number: 5C3Z-6211-AB$4.59 MSRP: $6.53You Save: $1.94 (30%)Ships in 1-3 Business DaysFord Explorer Sport Trac Connecting Rod Bearing

Part Number: 6L2Z-6211-C$14.54 MSRP: $20.72You Save: $6.18 (30%)Ships in 1-3 Business DaysFord Explorer Sport Trac Connecting Rod Bearing

Part Number: 6L2Z-6211-D$13.64 MSRP: $19.44You Save: $5.80 (30%)Ships in 1 Business DayFord Explorer Sport Trac Connecting Rod Bearing

Part Number: 5C3Z-6211-B$19.12 MSRP: $27.23You Save: $8.11 (30%)Ships in 1-3 Business DaysFord Explorer Sport Trac Connecting Rod Bearing

Part Number: 2L2Z-6211-AA$14.54 MSRP: $20.72You Save: $6.18 (30%)Ships in 1-3 Business DaysFord Explorer Sport Trac Connecting Rod Bearing

Part Number: 2L2Z-6211-BA$13.64 MSRP: $19.44You Save: $5.80 (30%)Ships in 1 Business Day

Ford Explorer Sport Trac Rod Bearing

The Rod Bearing is also known as the main bearing and it plays a very important function of holding and supporting the crank shaft and connecting rods as rotates with less friction. These are mostly plain bearings with the possible use of bimetal or trimetal construction of the bearing. The Bi-metal Rod Bearings possess a tubular aluminum alloy lining that can be backed with silicon for improved hardness and to check seizure. On the other hand, there are functional tri-metal Rod Bearings with copper based layer and lead tin copper overlay thereby giving more strength and fatigue life to the bearings. Ford Explorer Sport Trac models manufactured over the course of years may have used various kinds of Rod Bearings, the performance versions of which can be equipped with different, more durable materials with special anti-friction coatings. These Rod Bearings described here is designed to offer ideal oil clearance that is so important in the durability of the engine. There is always a importance to get the installation and alignment of the Rod Bearings appropriately done to guarantee that the Ford Explorer Sport Trac gets an adequate lubrication and performance at the same time.

We provide a wide range of Ford Explorer Sport Trac Rod Bearing at the best prices possible. If you need Ford Explorer Sport Trac Rod Bearing, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Explorer Sport Trac Rod Bearing Parts Questions & Experts Answers

- Q: What should be considered when examining and replacing Rod Bearing during an overhaul on Ford Explorer Sport Trac?A:When an engine is overhauled, it is advisable to fit new main and connecting rod bearings, while retaining the old ones for analysis, to deduce the state of the engine. The main root causes of bearing failure include, inadequate lubrication, dirt contamination, overloading of the engine and corrosion and all these root causes must be remedial before any reassembly is made to avoid repetition. When inspecting bearings they are withdrawn from their appropriate place and placed on a flat surface with a view of matching the defects with the crankshaft journal. Contaminants are brought into the engine during assembly or even through the filters, as well as during the machining processes, and our experiences show that such contaminants get lodged on the bearing surfaces and thereby create scores or gouges on the bearing material. To avoid such a failure, it is essential to clean every part carefully always change the oil and the filter frequently. This arises from one of the following causes: heat, overloading, leaking of oil and blocked passages and as a result can cause severe damage where the bearing material is entirely wiped off. Again, habits in driving are antonymous with bearing durability; for instance, in luging the engine or in short trips, there can be overload and corrosion respectively. Further, substandard mounting of bearings also provokes a lack of supplies of oil and high areas associated with failure.