My Garage

My Account

Cart

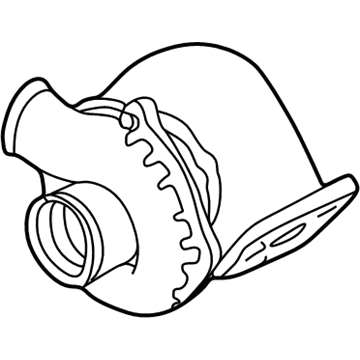

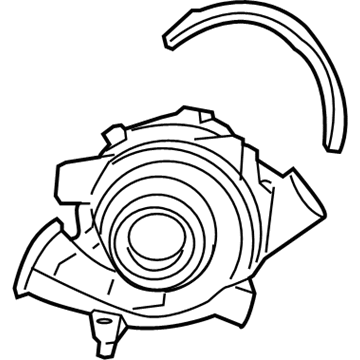

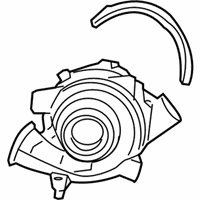

Genuine Ford Excursion Turbocharger

Turbo- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Turbochargers found

Ford Excursion Turbocharger Assembly

Part Number: F81Z-6K682-BARM$1285.38 MSRP: $2041.67You Save: $756.29 (38%)Ford Excursion Turbocharger Assembly

Part Number: 4C3Z-6K682-CBRM$1011.32 MSRP: $1538.33You Save: $527.01 (35%)Ships in 1 Business Day

Ford Excursion Turbocharger

The Turbocharger in Ford Excursion automobiles is one of those smart equipments that help the engine to gain greater power by the method called boost with the help of the turbine driven with exhaust gas. To enhance the volumetric efficiency, fuel efficiency is also enhanced without closing increasing the power output. The design consists of two main components: a turbine that is propelled by exhaust gaseous and a compressor which injects more air into the engine. Some of the stunning Turbochargers that have been used by Ford for Excursion models includes the twin-scroll Turbochargers and variable geometry turbochargers. All these changes are intended to minimise lag and provide more response than conventional turbochargers. Even though turbocharging is possible and good for both Petrol as well as for Diesel engines some complexities arise out of it like high temperature of exhaust and many times failures.

We provide a wide range of Ford Excursion Turbocharger at the best prices possible. If you need Ford Excursion Turbocharger, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Excursion Turbocharger Parts Questions & Experts Answers

- Q: What is the general information about turbochargers on Ford Excursion?A:This raises the amount of power that is available to the engine, and also increases fuel efficiency, especially when at high altitudes-all through the use of an exhaust gas driven turbine to compress the air that is used in the combustion chamber. The identification number of a turbocharger is stamped on the housing by means of an ID plate and this number is useful where a change of a turbocharger is required. Turbochargers are normally under emissions warranties and therefore, it is recommended to consult with a dealer on coverage. Boost in 7.3L engine is controlled by a wastage with the aid of a spring loaded actuator that allows the by passing of the turbine depending on the intake manifold pressure while an exhaust back pressure sensor feeds the PCM with relevant information. 6.0L and 6.4L engines use Variable Geometry Turbocharger (VGT) design in which boost is managed by variable vanes in the exhaust turbine section; actuator and control valve are incorporated in a unison ring for vane adjustment. Intercooler is used in models that are turbocharged as it cools the compressed air intake charge in order to improve combustion competence. While the turbocharger is a precision component that should be serviced with special tools only, some of the basic checks of the unit could be done by the user-presence of cracks or excessive wear, for example. The PET 2459 engine has a total capacity of 6.4L made up of two turbochargers-one for low pressure and the other for high pressure and is governed by the PCM. Any variation in sound made by the turbocharger should be attended to as it may be a result of problem that will require inspection of the exhaust manifold and connections. If noise is heard then the intake duct maybe taken out so that the compressor wheel can be swung to assess its freedom of movement because if it is constrained it can suggest lubrication problems. It is lubricated by pressurized, cooled, and filtered engine oil that is supplied with the engine block to the bearing housing and if the return line is blocked there will be burned oil on the turbine housing. The wastegate actuator controls the intake manifold air pressure to avoid over-boosting; to test it, applies pressure covering the wastegate; if the control rod does not move as required, then must be replaced.