My Garage

My Account

Cart

Genuine Ford Bronco Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

17 Pistons found

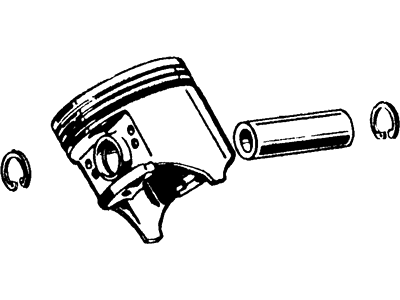

Ford Bronco PISTON AND PIN ASY

Part Number: E4TZ6108GB$37.75 MSRP: $51.58You Save: $13.83 (27%)Ships in 1-2 Business DaysFord Bronco Piston

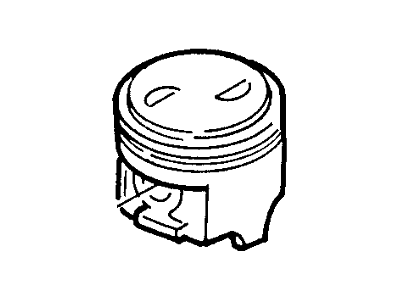

Part Number: LB5Z-6108-A$433.81 MSRP: $639.83You Save: $206.02 (33%)Ships in 1-3 Business DaysFord Bronco Piston & Pin Assembly

Part Number: F2ZZ6108DB$27.08 MSRP: $37.62You Save: $10.54 (29%)Ships in 1-2 Business DaysFord Bronco PISTON AND PIN ASY

Part Number: ML3Z-6108-D$165.53 MSRP: $242.00You Save: $76.47 (32%)Ships in 1-2 Business DaysFord Bronco Piston

Part Number: ML3Z-6108-E$165.53 MSRP: $242.00You Save: $76.47 (32%)Ships in 1-2 Business DaysFord Bronco Piston & Pin Assembly

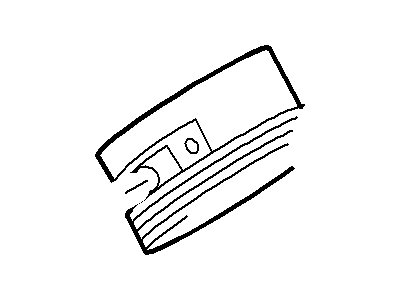

Part Number: F4TZ6108FB$16.70 MSRP: $23.20You Save: $6.50 (29%)Ships in 1-2 Business Days

Ford Bronco Piston

In Ford Bronco automobiles, the piston plays a critical role in the internal combustion engine through which energy produced during the combustion of fuel is converted into mechanical energy to move the car. The operation of the piston involve transmitting the force exerted by the expanding gases to the crankshaft through the piston and this is made possible by the shape of the piston and the use of piston rings which make the system gas-tight. Through the years, the Ford Bronco has employed different kinds of pistons in order to improve the power and fuel economy of the vehicle's engine. Several types of pistons have been used in Ford Bronco to meet particular engine specification and desired performance characteristics. For instance the trunk pistons which are commonly used in both petrol and diesel engines are designed to bear side loads and have oil rings for better lubrication. On the other hand racing pistons that are designed to work under high RPM conditions are made from materials such as aluminum alloys in order to provide strength with minimal weight. These different types of pistons show that Ford Bronco constantly adjust and modify its engine components for the purpose of improving the car's performance.

We provide a wide range of Ford Bronco Piston at the best prices possible. If you need Ford Bronco Piston, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Bronco Piston Parts Questions & Experts Answers

- Q: How to remove the piston/connecting rod assemblies on Ford Bronco?A:Before full disassembly of the piston and connecting rod assemblies there are few components that need to be detached,the cylinder head, the oil pan and the oil pump. First, eliminate the ridge at the top of each cylinder utilizing a ridge reaming tool because the existence of this ridge is dangerous to the pistons when undertaking the removal processes. After clearing the ridges, inversion of the engine is done with crank shaft upwards. When disconnecting the connecting rods, it will be necessary to check the end play with feeler gages; it should readily be possible to insert the thickness of a feeler gage between the first connecting rod and the Crankshaft throw; if the end play is excessive, it may be necessary to replace the connecting rods. Locate the connecting rods and the caps with the marks; in case the latter ones are missing, the engineer shall apply a center punch to put an indentation of the cylinders' number. Turn the connecting rod cap nuts gradually to be unfastened by hand; then take off the first connecting rod cap and the bearing insert without dropping the latter. For each of the connecting rod cap bolts to be removed, slip in a short length of plastic or rubber hose over the bolt before gently pounding the connecting rod/piston assembly out through the top of the engine, using a wooden or plastic hammer handle only. In case of resistance make sure that all the ridge material has been cleared. Perform it for the rest of the cylinders and once they are removed, fit back the connecting rod caps and bearing inserts to their corresponding rods and tighten the cap nuts only with fingers to avoid the wear and tear of the bearing surfaces.