My Garage

My Account

Cart

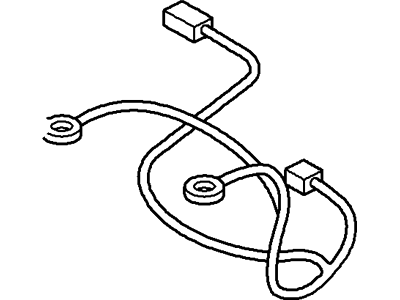

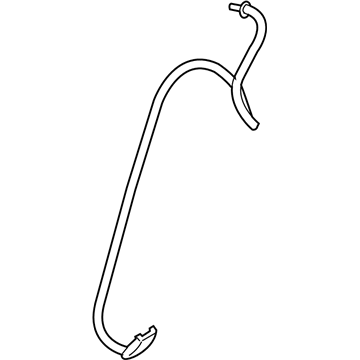

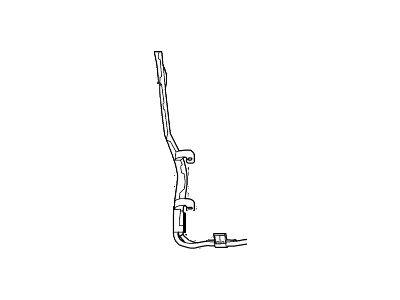

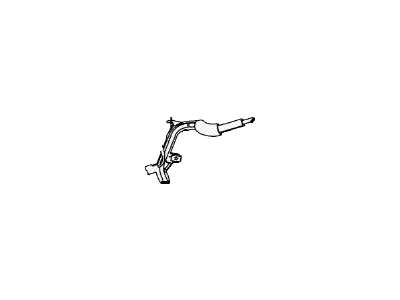

Genuine Mercury Mariner Battery Cable

Car Battery Cable- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

19 Battery Cables found

Mercury Mariner Battery Cable

The essential function of the Battery Cable in Mercury Mariner cars is to carry electric current from the battery to the starter and other electrical pieces of equipment required for the purpose of engine operation. These wires include a positive wire to carry power and a negative wire to act as the ground to make a closed-loop power system. From aging Mercury Battery Cable over time may get damaged or corroded or warped and that can restrain their efficiency and create a problem with starting. Many models of Mariner may have applied different types of Battery Cable which may have had different materials and construction. Periodical check of these cables is a must for normal functioning of the vehicle because the damaged or worn cables may cause malfunction of the battery as well as trouble in starting the engine. For optimal possibility, premium alternator Mercury Mariner Battery Cable are there to solve possible problems.

We provide a wide range of Mercury Mariner Battery Cable at the best prices possible. If you need Mercury Mariner Battery Cable, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Mercury Mariner Battery Cable Parts Questions & Experts Answers

- Q: How to inspect and replace battery cables on Mercury Mariner?A:Every now and then check the complete length of each battery cable to look for signs of, physical abuse, cracked or burnt insulation, and corrosion, because of bad connections you may have starting troubles and poor running engine. Inspect the cable-to-terminal junctions for any form of cracks, loose or exposed wire strands and any signs of corrosion; white, fluffy substances under the insulation mean corrosion and the cables must be replaced. Cable connection should always be disconnected from the negative terminal before disconnecting the positive terminal to avoid short circuiting of the battery, even if one is only replacing the positive cable. Remove the wires from the connection to battery and then from the other connection, pulling away from any clip or bracket that they may be connected to. Circuit trace each cable in order to know when to disconnect, a small hint, negative cable is usually positive to the engine or transaxle while the positive cable is connected to the starter motor solenoid. When buying new cables, take the old cables with you to make sure that you have a match since positive cables are larger, and red in color, but ground cables are black and smaller. Scrub the threads of the starter solenoid and ground connection with sand paper and apply a coat of anti-corrosive compound to avoid future problem. Fix the clamps on the negative terminal initially, and fix the new wire in such a manner that it does not stretch to reach the battery terminal which has positive charged. Don't forget you may have any brackets or clips that hold the cables in the engine area in place and then replace the ground cable to the battery terminal you loosened earlier. As with any newly-installed device, the Powertrain Control Module has to also re-adapt to its idle and fuel trim strategy.