My Garage

My Account

Cart

Genuine Mercury Bobcat Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Universal Joint found

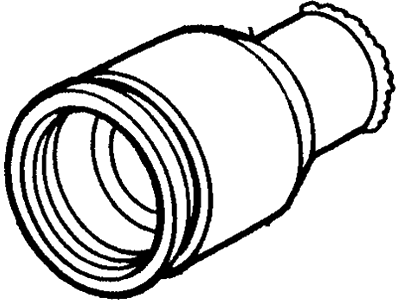

Mercury Bobcat Universal Joint

The Universal Joint in Mercury Bobcat vehicles is essential in linking the driveshaft to the axle assembly to enable some amount of turning as the suspension takes effect on rough roads or surfaces. This joint allows for the adjustments of power angle considering the change in components to promote power transmission. The Universal Joint normally has a cross with needle bearings which are fitted into hardened steel cups, clamped by clips and may be supplied pre-lubricated with grease. There are various types of U Joints which have been used on Bobcat vehicles; common ones are those which are used by manufactures and are normally hermitically sealed for the to use of greases, however, U Joints often come with grease zerk fittings where lubrication can be refilled as required. Worn U Joints can cause definable problem as: knocking and vibration that signal time for check up or replacement in order to enhance the performance the vehicle.

We provide a wide range of Mercury Bobcat Universal Joint at the best prices possible. If you need Mercury Bobcat Universal Joint, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Mercury Bobcat Universal Joint Parts Questions & Experts Answers

- Q: How do I overhaul the rear universal joint on Mercury Bobcat?A:This is easier than for the front universal joint as only two spider cups have to be removed. The Remaining cups simply slide off the spider journals, these being held in position by the two U-bolts and small lips on the pinion flange cup locations. Overhaul is otherwise.

- Q: How to overhaul front Universal Joint on Mercury Bobcat?A:Clean away all traces of dirt and grease from the snap-rings located on the ends of the bearing cups. Remove the snap-rings by pressing their open ends together with a pair of pliers, and lever them out with a screwdriver, If they are difficult to remove, tap the bearing cup face resting on the top of the spider with a soft-faced hammer which will ease the pressure on the snap-ring. Take off the bearing cups on the driveshaft yoke. To do this select two sockets from a socket spanner set, one large enough to fit completely over the bearing cup and the other smaller than the bearing cup. Open the jaws of the vise and with the sockets opposite each other and the universal joint in between, tighten the vise and so force the narrower socket to move the opposite cup partially out of the yoke into the larger socket. Remove the cup with a pair of pliers. Remove the opposite cup.and then free the yoke from the driveshaft. To remove the remaining two cups now repeat the instructions, or use a socket and hammer. Recover the thrust bearing from inside each cup and remove the seal from the base of each spider journal. Before reassembling, using new parts as necessary, thoroughly clean out the yokes and journals. Fit new oil seals to the spider journals and then assemble the needle rollers in the bearing cups with the assistance of some thin grease. Fill each bearing cup about one third full with a universal grease.not forgetting to refit the thrust bearings first. Refit the bearing cups on the spider and tap the bearings home so that they lie squarely in position. Replace the snap-rings and settle the cups by tapping the whole assembly with a soft faced hammer. Check that angular movement of the universal joint is free throughout its full range without signs of stiffness.

- Q: How to inspect Universal Joint on Mercury Bobcat?A:Wear in the needle roller bearings is characterised by vibration in drive-line, clunks' on taking up the drive, and in extreme cases of lack of lubrication, metallic squeaking, and ultimately grating and shrieking. It is easy to check if the needle roller bearings are worn with the driveshaft in position, by trying to turn the shaft with one hand, the other hand holding the rear axle pinion flange when the rear universal joint is being checked, and the front half coupling when the front universal is being checked, Any movement between the driveshaft and the front and rear half couplings is indicative of considerable wear. If worn, the old bearings and spiders will have to be discarded and repair kit, comprising new universal joint spiders, bearings, oil seals,and retainers purchased. Check also by trying to lift the shaft and noticing any movement in the joints. Examine the driveshaft splines for wear. If worn it will be necessary to purchase a new front half coupling, or if the yokes are badly worn, an exchange driveshaft. It is not possible to fit oversized bearings and journals to the trunnion bearing holes.