My Garage

My Account

Cart

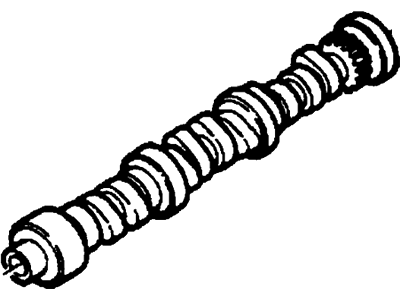

Genuine Ford Thunderbird Camshaft

Cam- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Camshafts found

Ford Thunderbird Camshaft

Part Number: E9SZ-6250-B$213.80 MSRP: $315.33You Save: $101.53 (33%)Ships in 1-3 Business DaysFord Thunderbird Camshaft

Part Number: 3W4Z-6250-DB$5.57 MSRP: $7.73You Save: $2.16 (28%)Ships in 1-2 Business Days

Ford Thunderbird Camshaft

Camshaft in Ford Thunderbird cars is one of the main components of the engine through which the procedure of intake and exhaust for the engine is controlled. Usually made of iron or steel, the camshaft works through retarders or lifters, push rods and rocking levers in the Over Head Valve (OHV) engines or tines in single Over Head Cam (SOHC) and double Over Head Cam (DOHC). Since its inception Ford Thunderbird has been through different forms of the camshaft and each of these plays different roles on the car's performance. Products such as performance camshafts give higher lift and duration to increase airflow and power but at the same time change the idle quality and vacuum. Other parameters including Lobe Separation Angle (LSA) additionally affects torque and RPM range hence allows unique performance according to driving requirement. In general, the camshaft plays a crucial role in enhancing the efficiency of the Thunderbird's engine as well as providing the right power output.

We provide a wide range of Ford Thunderbird Camshaft at the best prices possible. If you need Ford Thunderbird Camshaft, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Thunderbird Camshaft Parts Questions & Experts Answers

- Q: How to remove, inspect, install Camshaft and Camshaft Bearing on Ford Thunderbird?A:To check camshaft lobe lift and see how much its wear, unbolt the valve covers and the Rocker Arms and leave the push rods installed. Remove the number one piston and place it at Top Dead Centre on the compression stroke, then install a dial gauge on the engine so that it is facing the first push rod. Depress the dial indicator and start rotating the crankshaft slowly counterclockwise and stop at the point where the needle stops showing more readings and then starts to decrease noting the maximum cam lobe lift. Take this measurement and move the piston to TDC and do this for all the valves in the same firing order with the piston on the compression stroke. Finally, after performing the checks, refer to the corresponding specifications; if the measure of the lobe lift is under the required value, then it means wear and as a result a new camshaft will be needed. For removal, get off the pushrods, valve lifters, Timing Chain, as well as the camshaft sprocket; one must consider if the radiator or air conditioning condenser needs to come off. Take out the bolts of the camshaft thrust plate and check the thrust plate for signs of wear, if it is worn you replace it. Using the cam sprocket bolt turn it partially to act as a handle and slowly push the camshaft out without scratching the lobes against the bearings. After removal, camshaft should be cleaned and checked for damage and wear on bearing journals; if they are damaged, both camshaft and bearing will have to be replaced and it can only be done using special tools and equipment. Check the camshaft lobes for damage or discoloration, if they are still okay, the bearing journals should be used to measure for excessive wearing and thus the camshaft can be again used. The camshaft should be lubricated with grease or assembly lube before it was installed, and inserted into the engine with the help of a follower to prevent any bearing damage. Make sure that the Woodruff key is correctly positioned before it is fitted; grease the thrust plate and when it is fitted, ensure that the grooves are facing inwards. Put in the timing chain and sprockets then using clean oil lubricate the lifters before reinstalling them. The final part of the fixing process is based on step-by-step reversing of the exclusion acts, and before the engine turn on, replace the oil and oil filter.