My Garage

My Account

Cart

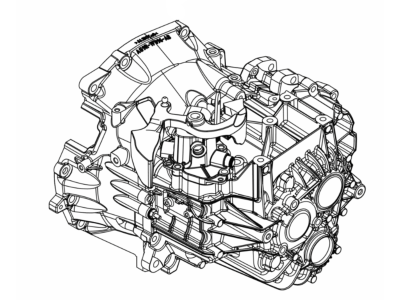

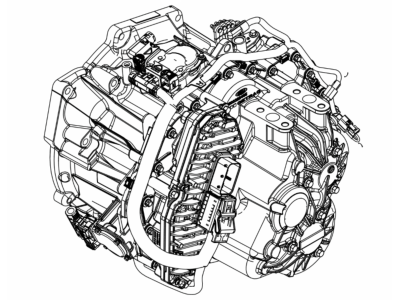

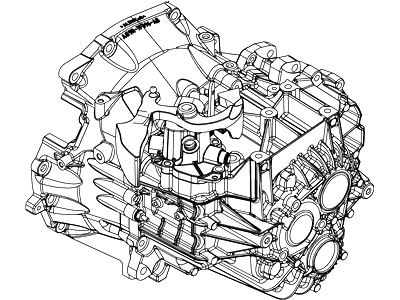

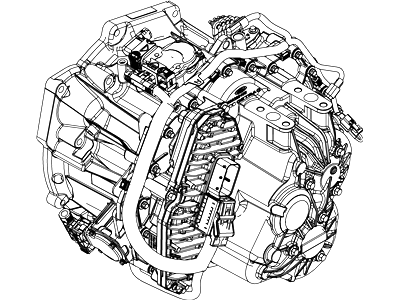

Genuine Ford Focus Transmission Assembly

Trans Assembly- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

53 Transmission Assemblies found

Ford Focus Transaxle Assembly

Part Number: CV6Z-7002-D$3937.62 MSRP: $5008.00You Save: $1070.38 (22%)Ships in 1-2 Business DaysFord Focus Automatic Transmission Assembly

Part Number: F1FZ-7000-P$5059.88 MSRP: $5998.67You Save: $938.79 (16%)Ships in 1-2 Business DaysFord Focus Automatic Transmission Assembly

Part Number: F1FZ-7000-VA$5059.88 MSRP: $5998.67You Save: $938.79 (16%)Ships in 1-2 Business DaysFord Focus Transaxle Assembly

Part Number: CV6Z-7002-B$4151.56 MSRP: $4917.33You Save: $765.77 (16%)Ships in 1-2 Business DaysFord Focus Automatic Transmission Assembly

Part Number: BV6Z-7000-K$5059.88 MSRP: $5998.67You Save: $938.79 (16%)Ships in 1-2 Business DaysFord Focus Automatic Transmission Assembly

Part Number: BV6Z-7000-G$5059.88 MSRP: $5998.67You Save: $938.79 (16%)Ships in 1-2 Business DaysFord Focus Automatic Transmission Assembly

Part Number: BV6Z-7000-M$5059.88 MSRP: $5998.67You Save: $938.79 (16%)Ships in 1-2 Business DaysFord Focus Transaxle Assembly

Part Number: G1FZ-7002-A$3972.36 MSRP: $4704.00You Save: $731.64 (16%)Ships in 1-2 Business DaysFord Focus Transaxle Assembly

Part Number: CV6Z-7002-C$4151.56 MSRP: $4917.33You Save: $765.77 (16%)Ships in 1-2 Business DaysFord Focus Automatic Transmission Assembly

Part Number: BV6Z-7000-F$5059.88 MSRP: $5998.67You Save: $938.79 (16%)Ships in 1-2 Business DaysFord Focus Transaxle Assembly

Part Number: CV6Z-7002-A$3573.64 MSRP: $4229.33You Save: $655.69 (16%)Ships in 1-2 Business DaysFord Focus Automatic Transmission Assembly

Part Number: F1FZ-7000-A$4163.88 MSRP: $4932.00You Save: $768.12 (16%)Ships in 1-2 Business DaysFord Focus Automatic Transmission Assembly

Part Number: BV6Z-7000-L$5059.88 MSRP: $5998.67You Save: $938.79 (16%)Ships in 1-2 Business DaysFord Focus Automatic Transmission Assembly

Part Number: BV6Z-7000-E$5059.88 MSRP: $5998.67You Save: $938.79 (16%)Ships in 1-2 Business DaysFord Focus Automatic Transmission Assembly

Part Number: 8M5Z-7000-A$3379.88 MSRP: $3998.67You Save: $618.79 (16%)Ships in 1-3 Business DaysFord Focus Automatic Transmission Assembly

Part Number: 8S4Z-7000-ARM$3155.88 MSRP: $3732.00You Save: $576.12 (16%)Ships in 1-3 Business DaysFord Focus Transaxle Assembly

Part Number: FV6Z-7002-A$2929.08 MSRP: $3472.00You Save: $542.92 (16%)Ships in 1-3 Business DaysFord Focus Transaxle Assembly

Part Number: CV6Z-7002-Y$2929.08 MSRP: $3472.00You Save: $542.92 (16%)Ships in 1-3 Business DaysFord Focus Transaxle Assembly

Part Number: 8S4Z-7002-C$3120.04 MSRP: $3689.33You Save: $569.29 (16%)Ships in 1-3 Business DaysFord Focus Transaxle Assembly

Part Number: H1FZ-7002-A$6476.12 MSRP: $7694.67You Save: $1218.55 (16%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 53 Results

Ford Focus Transmission Assembly

We provide a wide range of Ford Focus Transmission Assembly at the best prices possible. If you need Ford Focus Transmission Assembly, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Focus Transmission Assembly Parts Questions & Experts Answers

- Q: How to remove and install the automatic transaxle on Ford Focus?A:To fully disengage the transaxle, one has to take off various parts including the air cleaner, intake duct, the front panel air intake, resonator, and air intake tube, the battery, and the battery tray. Unscrew the vacuum line at the EGR valve and on models through 2002, remove the round plastic plug cover at the front of the suspension strut and loosen the center bolt, while 2003 models and above, you will work with the three nuts on the left front strut. Unbolt the selector cable/fluid filler tube support bracket, unbolt the front wheel and drive axal/hub nuts and then jack up the front part of the car and take of the four front wheels. Remove the connector from the selector cable for transaxle lever and from the vehicle/output shaft speed sensor, and from the turbine shaft speed sensor and from the transaxle range sensor. Take off the front part of the exhaust pipe and both drive axles and clean the nearby areas of the fluid supply pipe and the fluid return pipe. To get to the starter motor, it is necessary to unscrew the union nuts to disconnect the fluid pipes and to remove the engine/transaxle rear mount. Sustain the engine/transaxle, eliminate the left-hand mount, and gradually cancel the nuts that coddle the upper segment of the left-hand mount. Disconnect the lower section of the engine left arm then disconnect the transaxle fluid filler tube and its cover to get a view at the torque converter nuts; while in this position turn the engine clockwise until all the nuts appear in line of sight. Flip the car and slide the transaxle to the middle of the car then use a jack to hold it from below and remove the flange bolts if there is something that will stop the transaxle from falling lower remove it. Once the transaxle has been fully lowered ensure that you lock the torque converter into the required position. To install it, first, clean the contact surfaces, then fix the torque converter onto its place and lift upward the transaxle until it is to be in contact with the driveplate. Secure the transaxle to engine flange bolts, position the torque converter relative to the driveplate and put on the torque converter nuts. Replace both the LH lower and upper engine mounts, tighten the rear through bolts of the mount and withdraw the support. Repeat the opposite sequence for other additional replacement operations; make sure to reinstall the starter motor, and driveshafts; also, fasten all loose connections and tighten; adjust the selector cable and check the transaxle fluid level before moving the car. A word of caution is that the PCM will require some learning period after the battery has been disconnected.

Related Ford Focus Parts

Browse by Year

2018 Transmission Assembly 2017 Transmission Assembly 2016 Transmission Assembly 2015 Transmission Assembly 2014 Transmission Assembly 2013 Transmission Assembly 2012 Transmission Assembly 2011 Transmission Assembly 2010 Transmission Assembly 2009 Transmission Assembly 2008 Transmission Assembly 2007 Transmission Assembly 2006 Transmission Assembly 2005 Transmission Assembly 2004 Transmission Assembly 2003 Transmission Assembly 2002 Transmission Assembly 2001 Transmission Assembly