My Garage

My Account

Cart

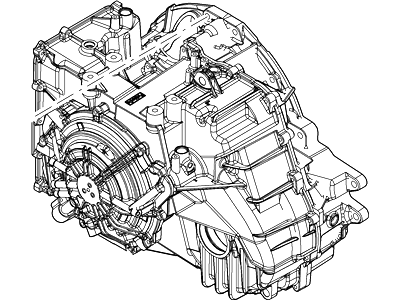

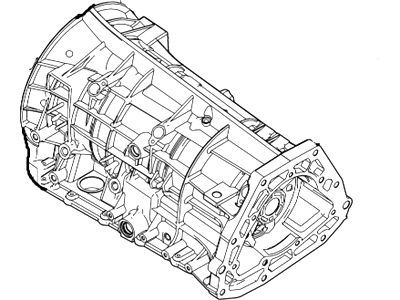

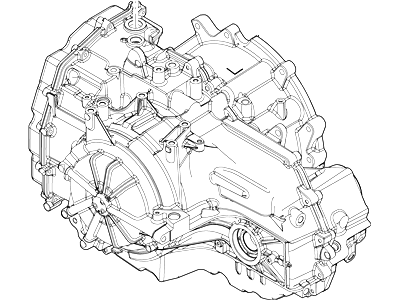

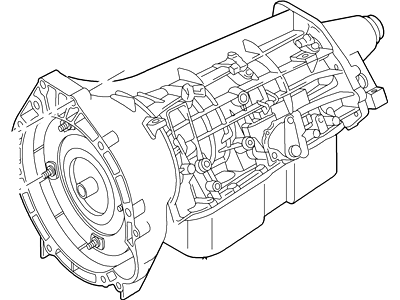

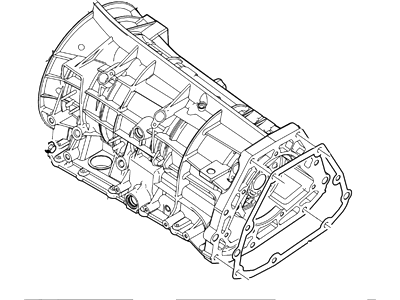

Genuine Ford Explorer Transmission Assembly

Trans Assembly- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

146 Transmission Assemblies found

Ford Explorer Reman Automatic Transmission Assembly

Part Number: GB5Z-7000-BRM$3603.88 MSRP: $4265.33You Save: $661.45 (16%)Ships in 1-3 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: DA5Z-7000-M$3715.88 MSRP: $4398.67You Save: $682.79 (16%)Ships in 1-2 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: FB5Z-7000-D$3603.88 MSRP: $4265.33You Save: $661.45 (16%)Ships in 1-2 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: DA8Z-7000-D$3715.88 MSRP: $4398.67You Save: $682.79 (16%)Ships in 1-2 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: L1MZ-7000-R$5059.88 MSRP: $5998.67You Save: $938.79 (16%)Ships in 1-3 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: DA8Z-7000-ARM$3715.88 MSRP: $4398.67You Save: $682.79 (16%)Ships in 1-3 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: DA8Z-7000-GRM$3715.88 MSRP: $4398.67You Save: $682.79 (16%)Ships in 1-3 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: L1MZ-7000-Q$5059.88 MSRP: $5998.67You Save: $938.79 (16%)Ships in 1-3 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: 9L2Z-7000-DRM$3379.88 MSRP: $3998.67You Save: $618.79 (16%)Ships in 1-3 Business DaysFord Explorer Reman Automatic Transmission Assembly

Part Number: GB5Z-7000-ARM$3603.88 MSRP: $4265.33You Save: $661.45 (16%)Ships in 1-3 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: L1MZ-7000-T$5059.88 MSRP: $5998.67You Save: $938.79 (16%)Ships in 1-3 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: BB5Z-7000-L$3603.88 MSRP: $4265.33You Save: $661.45 (16%)Ships in 1-3 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: BA5Z-7000-E$3943.91 MSRP: $4798.67You Save: $854.76 (18%)Ships in 1-3 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: BB5Z-7000-LRM$3603.88 MSRP: $4265.33You Save: $661.45 (16%)Ships in 1-3 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: BB5Z-7000-S$3939.88 MSRP: $4665.33You Save: $725.45 (16%)Ships in 1-3 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: 7L2Z-7000-CRM$3379.88 MSRP: $3998.67You Save: $618.79 (16%)Ships in 1-3 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: 4L2Z-7000-ABRM$3379.88 MSRP: $3998.67You Save: $618.79 (16%)Ships in 1-3 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: 6L2Z-7000-FRM$3379.88 MSRP: $3998.67You Save: $618.79 (16%)Ships in 1-3 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: AL2Z-7000-D$3379.88 MSRP: $3998.67You Save: $618.79 (16%)Ships in 1-3 Business DaysFord Explorer Automatic Transmission Assembly

Part Number: EE9Z-7000-ARM$3603.88 MSRP: $4265.33You Save: $661.45 (16%)

| Page 1 of 8 |Next >

1-20 of 146 Results

Ford Explorer Transmission Assembly

We provide a wide range of Ford Explorer Transmission Assembly at the best prices possible. If you need Ford Explorer Transmission Assembly, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Explorer Transmission Assembly Parts Questions & Experts Answers

- Q: How to remove and install the transmission on Ford Explorer?A:To eliminate the transmission, one has to unscrew the negative terminal of the battery and safely lift the car using the jack to place it on the stands, if the car uses Automatic Ride Control, its switch shall be off. Remove the transmission pan and dump its contents, replace it back in its rightful position. On the 4WD models, you have to take out the transfer case, and unscrew the starter, which you should then secure somewhere in order to access the torque converter head nuts. Paint one of the studs and the torque converter with white paint so that they would be easy to reconnect. Loosen the four torque converter-to- drive plate nuts, while turning the crankshaft anticlockwise to get better access. For the 2 wheel drive models, the driveshaft should be unbolted and the extension housing covered to reduce cases of moister and dirt penetration. Remove the speedometer cable from the VSS if there is a cable or pull out the electrical connector in case of electric VSS. Pull the transmission Shift Cable / kickdown cable out of the transmission, then unplug electrical connectors on the harness, stow the harness aside. Jack up the transmission by placing a transmission jack below the transmission and exert some pressure to lift it slightly and use chains to secure it to prevent any accidents. Eliminate the transmission mount and cross member; place jack under the engine and use a block of wood at the oil pan. Lower the engine and transmission slightly and unbolt the two transmission oil cooler lines and plug them. As for the lower transmission-to-engine bolts, and dipstick tube, then, they must be undone with the same manner of bolts that secure the tube to the cylinderhead. Safeguard the transmission on the jack and take off the two upper transmission to engine bolts. Slowly shift the transmission backward in order to come off the dowel pins on engine block; ensure that torque converter has come off the drive plate. To install, reverse the above process you have to ensure that the convert hub is tightly engaged in the pump gear and ensure that the bolt drive lugs and the drain plug are perfectly located in the drive plate holes. After this raise the transmission to a parallel position with the ground to ensure that the gears mesh together properly, align the hole in the drive plate with the stud with the help of the white marks that have been painted on the plate then slowly advance the transmission forward until it engages. Fit the numerous drive plate-to-converter nuts, using first one nut through the pilot hole and then fasten it, followed by the other nuts. Loosen the shift cable, decrease the height of the car, add the required type of the transmission fluid, start the engine, and examine the presence of any leakage.

Related Ford Explorer Parts

Browse by Year

2023 Transmission Assembly 2022 Transmission Assembly 2021 Transmission Assembly 2020 Transmission Assembly 2019 Transmission Assembly 2018 Transmission Assembly 2017 Transmission Assembly 2016 Transmission Assembly 2015 Transmission Assembly 2014 Transmission Assembly 2013 Transmission Assembly 2012 Transmission Assembly 2011 Transmission Assembly 2010 Transmission Assembly 2009 Transmission Assembly 2008 Transmission Assembly 2007 Transmission Assembly 2006 Transmission Assembly 2005 Transmission Assembly 2004 Transmission Assembly 2003 Transmission Assembly 2002 Transmission Assembly 2001 Transmission Assembly 2000 Transmission Assembly 1999 Transmission Assembly 1998 Transmission Assembly 1997 Transmission Assembly 1996 Transmission Assembly 1995 Transmission Assembly