My Garage

My Account

Cart

Genuine Ford Bronco II Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

34 Drive Belts found

| Page 1 of 2 |Next >

1-20 of 34 Results

Ford Bronco II Drive Belt

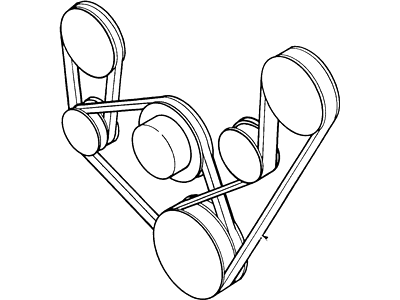

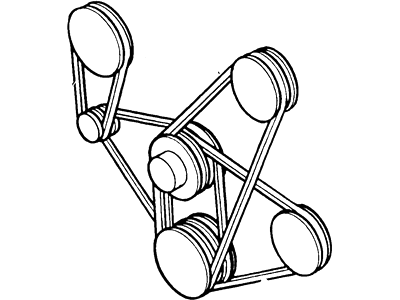

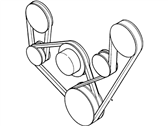

Drive Belt in the Ford Bronco II automobiles is used to link the engine to a number of units including the alternator and the A/C compressor. Usually a serpentine belt is used, which passes around these items and connect to the crankshaft pulley. This design enables efficient supply of power to the parts to enable them function properly. It is evident that the major Ford Bronco II models employ V-belts and serpentine belts and the latter is preferred since it causes little slippage and offers improved adjustment. Most Drive Belts have a lifespan of 100,000 miles, however, they may degrade before that point requiring a replacement to avoidany wear and tear to both the parts and the engine. The Drive Belt has critical functions on performance of the Ford Bronco II via its efficiency and sturdiness.

We provide a wide range of Ford Bronco II Drive Belt at the best prices possible. If you need Ford Bronco II Drive Belt, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Bronco II Drive Belt Parts Questions & Experts Answers

- Q: How to inspect, adjust, and remove/install drive belts on Ford Bronco II?A:Inspect the belts for signs of glazing or cracking, as a glazed belt will appear perfectly smooth from slippage, while a good belt will show a slight texture of fabric. Cracks typically begin at the inner edge and extend outward. All worn or damaged drive belts should be replaced immediately, and it is advisable to replace all drive belts simultaneously as a preventive maintenance measure during service. To check belt tension, press on the belt at the center of its longest straight run; it should give about ¼-½ inch. A loose belt will slip, while a belt that is too tight can damage bearings in the driven unit. The driven units, such as the alternator, power steering pump, or compressor, have a bolt that can be loosened to allow movement for belt adjustment, and sometimes the pivot bolt must also be loosened. For removal, loosen the accessory being driven and move it on its pivot point to free the belt, then remove the belt. If an idler pulley is present, it may only be necessary to loosen it to provide enough slack to slip the belt off. On engines with multiple driven accessories, several or all belts may need to be removed to access the one that requires replacement.