My Garage

My Account

Cart

Genuine Ford Bronco Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Flywheels found

Ford Bronco Flywheel Assembly

Part Number: D5TZ-6375-A$57.00 MSRP: $83.33You Save: $26.33 (32%)Ships in 1-3 Business DaysFord Bronco Flywheel Assembly

Part Number: HL3Z-6375-A$59.19 MSRP: $86.53You Save: $27.34 (32%)Ships in 1-3 Business DaysFord Bronco FLYWHEEL ASY

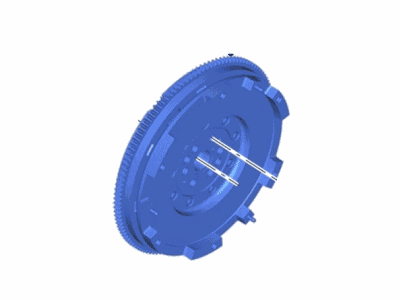

Part Number: MB3Z-6477-A$729.12 MSRP: $1085.00You Save: $355.88 (33%)Ships in 1-2 Business DaysFord Bronco Flywheel Assembly

Part Number: JR3Z-6375-A$68.06 MSRP: $105.23You Save: $37.17 (36%)Ships in 1-3 Business Days

Ford Bronco Flywheel

We provide a wide range of Ford Bronco Flywheel at the best prices possible. If you need Ford Bronco Flywheel, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Bronco Flywheel Parts Questions & Experts Answers

- Q: How do you remove and inspect the flywheel/driveplate from the crankshaft on Ford Bronco?A:Remove the transmission and, for models with a manual transmission, take off the clutch housing. Mark the relationship of the flywheel/driveplate to the crankshaft to ensure installation in the same position. To prevent the crankshaft from turning, wedge a large screwdriver or prybar between the ring gear teeth and the engine block, ensuring the tool bears against the block as the crankshaft moves, without pushing against the oil pan. Remove the flywheel/driveplate retaining bolts from the crankshaft flange, then pull the flywheel/driveplate straight back; if it's stuck, wiggle it from side to side. Inspect the flywheel surface for scoring, heat marks, cracks, and warpage. If any issues are found, take the flywheel to an automotive machine shop for resurfacing or replace it if cracked. Installation is the reverse of removal, with retaining bolts coated in thread-locking compound and tightened in a criss-cross pattern to the specified torque.